3D Systems – Geomagic Control X Software from Oqton

3D Inspection and Metrology Software

We’re making inspection simpler. Capture and automate the processing of data from 3D scanners and other devices. Measure, understand, and communicate inspection results with next to no human interaction.

Geomagic Control X is a professional metrology software that lets you capture and process the data from 3D scanners and other devices to measure, understand, and communicate inspection results to ensure quality everywhere.

With Control X, more people in your organization can:

- Measure faster

- Measure more often

- Measure more completely

- Measure anywhere

Quality Assurance needs to be in every production environment. We’re making 3D scan-based inspection easier.

Agile

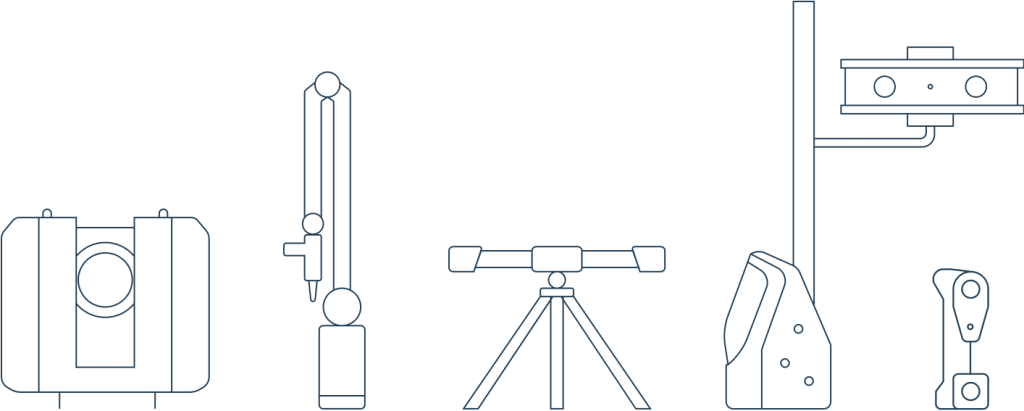

Integrate with any scanner or PCMM arm.

Fast

Collect and analyze huge data sets, 7x faster than CMMs.

Simple

Automate repetitive and complex tasks easily to get results with little or no training

Hardware Agnostic

Improve inspection agility by integrating with most scanners and PCMMs on the market.

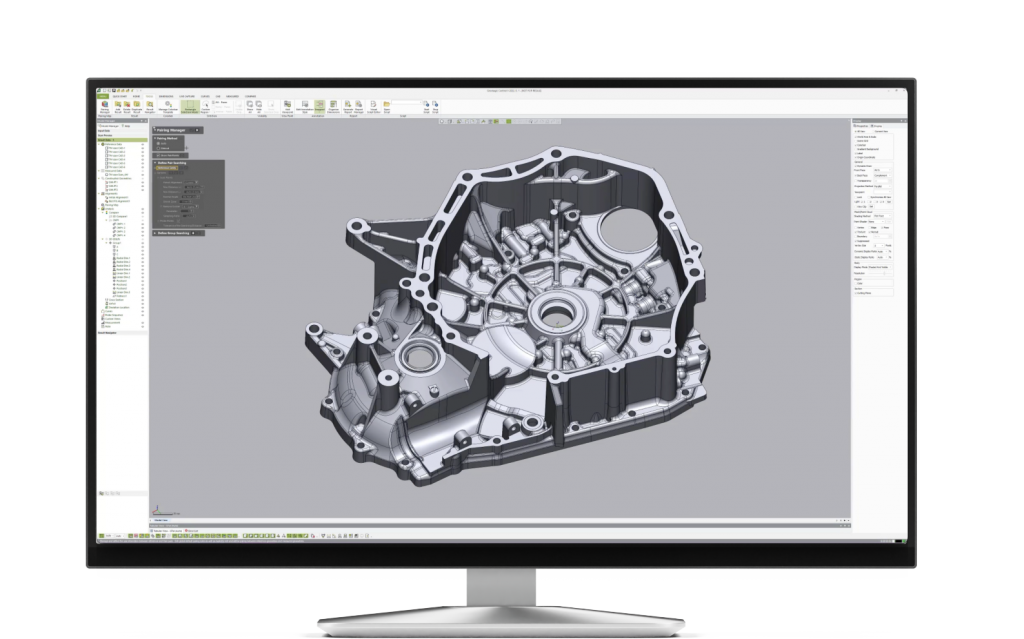

Built on a CAD kernel

Intuitive UI makes complex metrology tasks more accessible.

Simple to use automation tools

Prevent false part scrappage by automating repetitive tasks with straightforward visual scripting functionality.

Intelligent measurement and feature recognition

Reduce costly downtime by measuring right first time, every time.

Streamline production

Learn from manufacturing mistakes, adapt your production process, build better parts.

Applications

Benefits for every industry

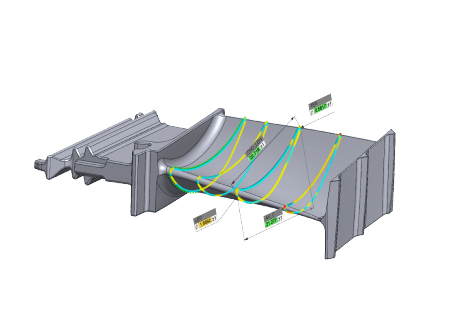

Aerospace

Recreate blades and blisks with efficient turbine blade averaging workflows.

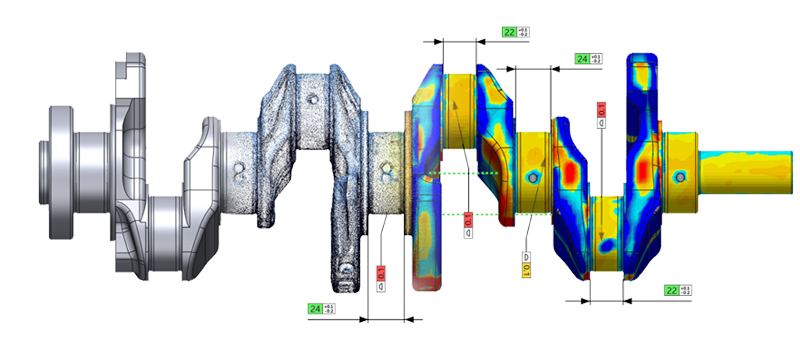

Automotive

Fast and accurate volumetric reporting, perfect for costing and planning additive production of heat exchangers.

Healthcare

Automate a set inspection routine, even when the reference geometry changes from patient to patient.

Electronics

Accurately report out surface area data for electro-plating components.

Mining

Wear analysis and replacement prediction of important components such as ball mills.

Research

Measurement of deformation of material exposed to external events such as explosions or radiation.

The Highlights

Bring the power of 3D scan-based inspection to more people in more places.

Direct scanner control

Capture data directly inside Geomagic Design X, or work with scan data from any scanner

Automation

Customize and maximize inspection throughput with Visual Scripting and Automation Server capabilities.

Airfoil analysis

Quickly and intuitively gather profile measurements, including twist analysis, for turbines, blisks, blades and more.

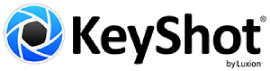

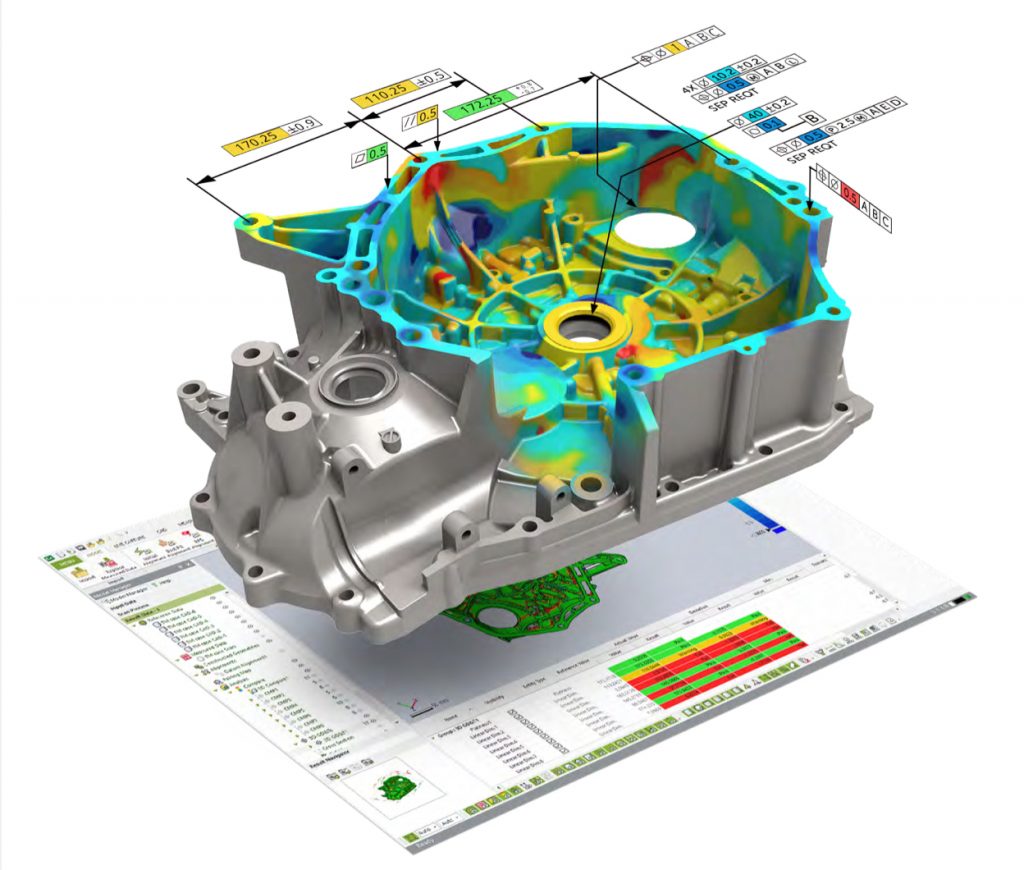

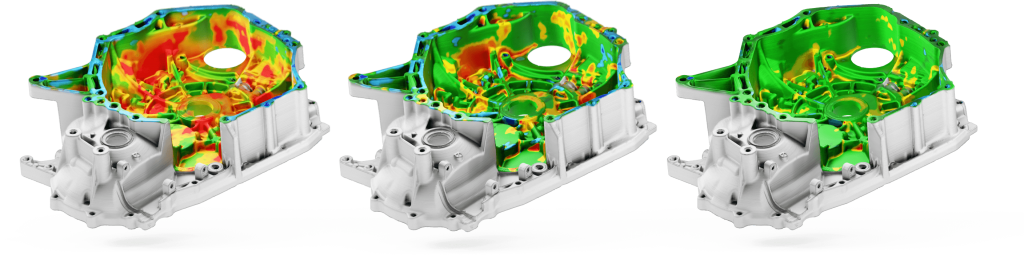

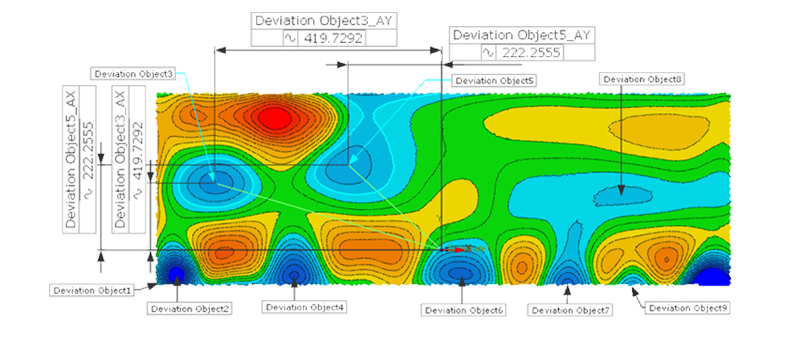

Deviation location

Scan, analyze and report surface defects and variations.

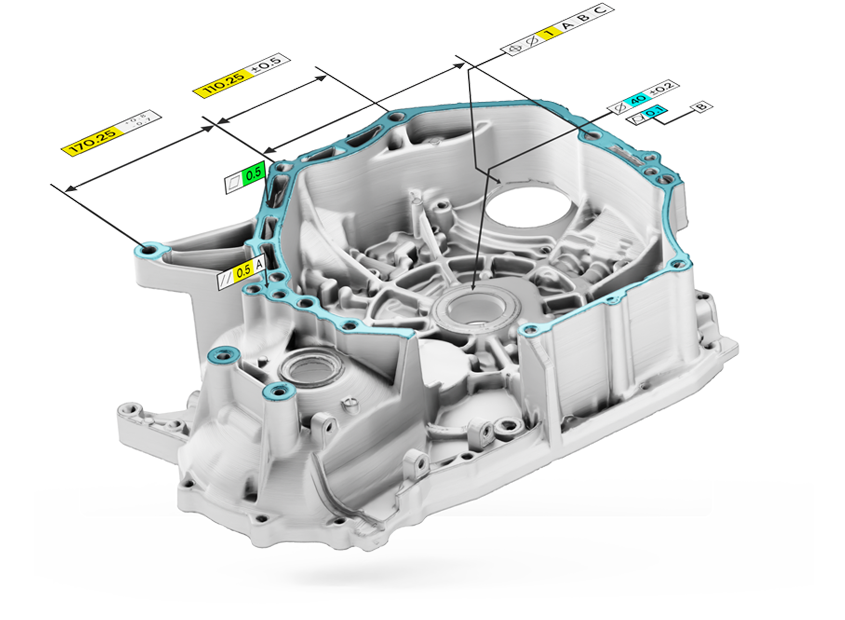

Annotations & dimensioning

Use customizable annotations, CAD-aware dimensioning, PMI support and comprehensive GD&T callouts.

Custom reporting

Analyze multiple results and easily create professional inspection reports from them.

(official website : Oqton.com)