Formlabs Form 4BL

A New Era of Dental Manufacturing

HIGH THROUGHPUT: More parts per print with fewer interactionsVOLUME

Blazing Speed: 32 models in 14 min

Accurate: Repeatable accuracy you can count on

Versatile: Effortlessly create parts for high volume dental applications

Maximum Uptime: Large format 3D printing that you can depend on

Streamlined: Easy, efficient operations optimized for large-scale production

More throughput, fewer interactions.

Fit up to 32 flat or 75 vertical dental models in one print.

BUILD VOLUME

4.6x

Larger build volume compared to Form 4B

FORM 4BL

353 x 196 x 350 mm

(13.9 x 7.7 x 13.8 in), 24.2 L

INTERACTIONS

Up to 3x fewer interactions

compared to Form 4B

Speed at scale. Produce 32 models in 14 minutes*.

*Print time based on clear aligner models printed with Fast Model Resin at 160µm

**Printers with smaller build platforms might take 3 builds to achieve the same throughput as Form 4BL. In these cases, we summed up the print times of these builds.

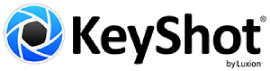

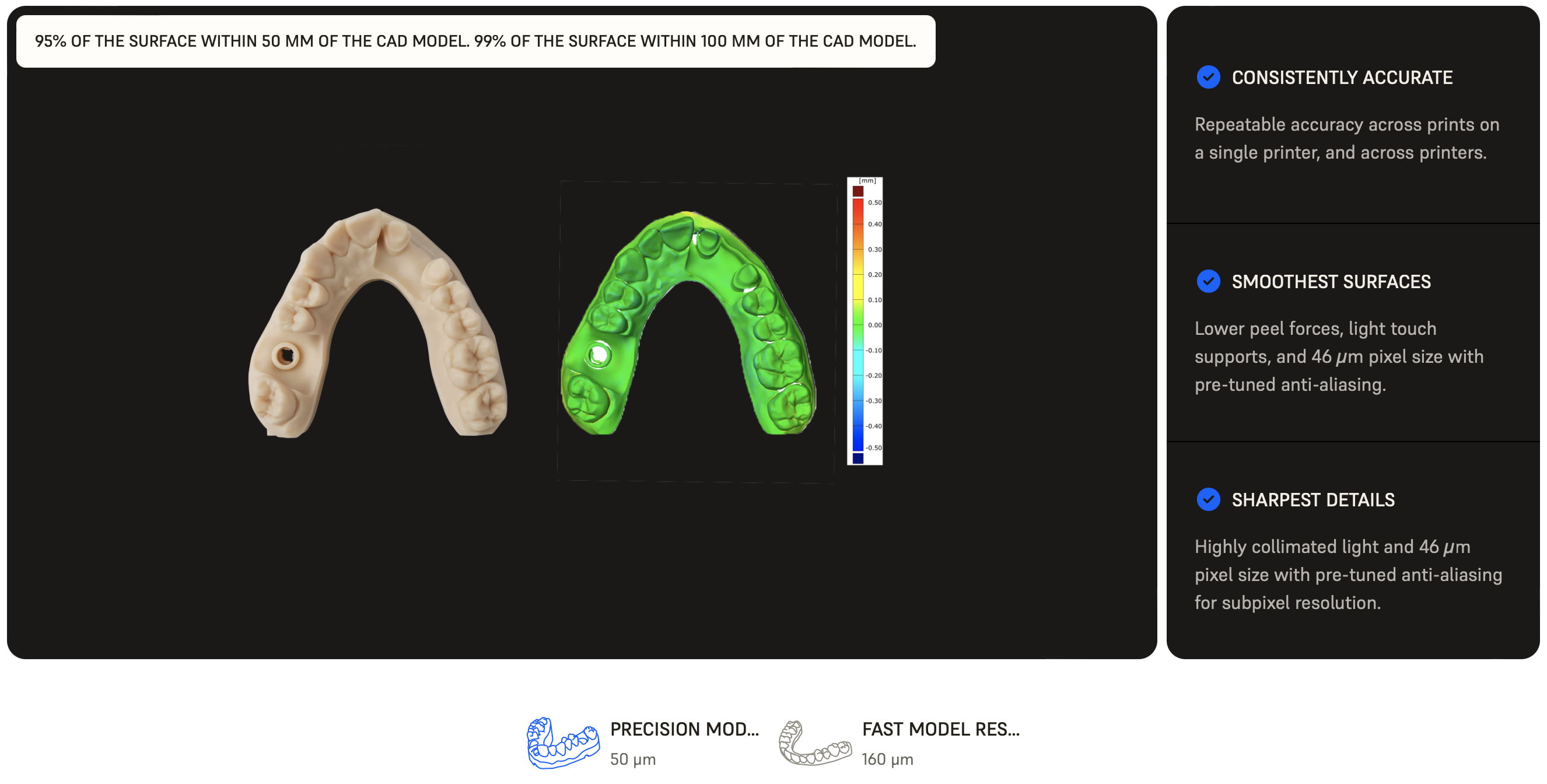

Repeatable accuracy you can count on.

Effortlessly create parts for high volume dental applications. Print any resin with Open Material Mode.

SURGICAL GUIDES Faster and safer surgeries with Surgical Guide Resin

CLEAR ALIGNER MODELS Blazing fast aligners and retainers with Fast Model Resin

ALL-ON-X Industry-leading intraoral flexural strength with Premium Teeth Resin

OCCLUSAL SPLINTS AND GUARDS Flexible splints with Dental LT Comfort Resin

DIAGNOSTIC MODELS Effective communication models with Grey Resin

RESTORATIVE MODELS A perfect fit every time with Precision Model Resin

TEMPORARY RESTORATIONS Accurate and fast temporary restorations Accurate and fast temporary restorations

CUSTOM IMPRESSION TRAYS Precise physical impressions with Custom Tray Resin

DIRECT COMPOSITE RESTORATIONS Hassle-free restorative appointments with IBT Flex Resin

INDIRECT BONDING TRAYS Efficient bracket placement with IBT Flex Resin

PATTERNS FOR CASTING AND PRESSING Removable partial dentures with Castable Wax Resin

OPEN MATERIAL MODE Any 405 nm photopolymer resin using customizable print settings.

Maximum uptime and yield.Large format 3D printing you can depend on.

Validated Print Settings

Formlabs optimization engineers put hundreds of printed parts to the test to ensure each material performs to the most reliable standards, right out of the box.

Intelligent Control Systems

Six control systems precisely measure and maintain the temperature, resin level, print forces, and print status inside your printer.

Long-Lasting Consumables

Robust hardware that was engineered for years of use.

Tank rated for >75,000 layers for all materials.

Light Processing Unit rated for >750,000 layers.

Factory Calibration

60-point calibration and quality control inspection before your printer even leaves the factory.

Remote Monitoring

Monitor your prints and manage your printers from anywhere with an integrated camera, preventative maintenance reminders, and our free Dashboard software.

Dental Experts

Our Dental Service Plan offers personalized onboarding, proactive check-ins, and industry-leading phone and email support, with on-site assistance available upon request.

Streamlined for large-scale production. Easy onboarding, efficient operations, and fewer touchpoints.

So intuitive that anyone can learn to print in 15 minutes.

- Import your model and prepare your print.

- Automatic print setup based on indication

- Convert scans to 3D printable models with Scan to Model

- Seamless integration with scanners and CAD software

- Advanced support generation and manual editing

- Load a material and click print.

- Validated print settings

- No-mess cartridges and tanks

- Automatic and fast resin dispensing

- Remove, wash, cure.

- Quick release part removal*

- Automatic part cleaning

- Precision post-curing for peak material properties

- *Build Platform Flex L is not yet available. Coming soon.

- Finish your part.

- Light touch supports for quick, clean support removal

Backlight

The Backlight Unit generates a uniform area projection of an ultra-high power light using 145 LEDs and collimating lenses. It cures resin quickly and precisely, delivering blazing fast print speeds with excellent print quality and accuracy anywhere on the build platform.

- Unmatched optical power: 16 mW/cm² delivered to the print plane.

- Plano-convex lens array and optical baffle: Creating highly collimated and uniform light, even at high power.

- Extremely long lifetime, due to an integrated cooling system.

Light Processing Unit

The Light Processing Unit 4L (LPU 4L) precisely masks light from the backlight unit into the shape of a printed layer. Together, the Backlight Unit and LPU 4L enable you to print with extreme speed, accuracy, and print quality anywhere on the build platform. The LPU 4L is long -lasting, resistant to accidental damage, and easy to replace.

- Unmatched light transmission:Delivering 16 mW/cm² to the print plane for blazing fast print speeds.

- Unmatched lifetime: Delivers consistent print performance before replacement.

- High resolution: 46 μm pixel size for sharp details, smooth surface finish, and accurate tolerances.

- Damage resistant: Aluminum frame, top surface coating, and force detection protect the LPU from accidental damage.

- Easy to replace in a few minutesusing a single tool that is provided and stored inside the printer.

Release Texture

A proprietary, microtextured optical film provides airflow between the resin tank and the Light Processing Unit. This film is built into the Light Processing Unit and sits at the top of it. This significantly reduces peel forces so you can print at blazing fast speeds without sacrificing surface finish, fine features, accuracy, or reliability.

- Reduces peel forces.

- Robust and maintenance-free:Provides airflow and reduces peel forces passively. There are no pumps or actuators that could break and require maintenance.

Intelligent Control Systems

Six onboard control systems precisely measure and maintain the temperature, resin level, print forces, and print status inside your printer. Together, they ensure consistent, reliable performance and prevent common failures, for the same results on every printer and every print.

- Camera: Enables remote monitoring and troubleshooting, but can be disabled for privacy.

- Resin Level Sensor: Measures the exact amount of resin in the Resin Tank.

- Force Sensor: Optimizes print speed and print quality across materials and geometries.

- Resin Temperature Sensor:Monitors resin temperature

- Mixer Debris Sensing: Checks for cured resin in the tank to quickly detect print failures.

- Printer Leveling Sensor: Ensures the printer is flat for accurate measurement and distribution of resin in the tank.

Resin Tank

The Form 4L Resin Tank holds liquid resin inside the printer and provides a substrate for the liquid resin to cure against, using a dual-layer flexible film stack. It significantly reduces peel forces so you can print at blazing fast speeds without sacrificing surface finish, fine features, accuracy, or reliability.

- Minimal peel forces: Using a dual-layer flexible film that enables the gentle separation of newly printed layers.

- Unmatched lifetime: Delivers consistent print performance for >75,000 layers, with any Formlabs resin. Top film is chemically inert and stretchy. Bottom film is strong and durable to reduce scratches and punctures. Film frame is stamped steel to maintain high film tension.

- Easy to use: Stackable design, integrated lid, simple latches, easy-pour spout, and oversized volume to protect against accidental spills.

Automatic Resin Handling

Integrated system that dispenses resin quickly, accurately, and with minimal waste, while making it easy to switch materials. Print without having to worry about your printer running out of resin and switch materials in <1 minute. Form 4BL is still one of the only SLA printers on the market to offer this feature.

- Faster resin dispensing: Fill an empty resin tank in 2-8 minutes with most resins. Features a redesigned valve system for 5-10x faster filling than Form 3BL.

- 63% less plastic waste: The redesigned cartridge body uses less plastic, while still reliably storing one liter of resin.

- 30% smaller form factor:Redesigned cartridge takes up less shelf space.